How TeE-Times Works For You

Tech Efficiency on Button Press

Running a business on data is critical. It creates consistency and accountability, and the staff will know exactly where to put the effort to get better. TeE-Times will provide a series of important KPIs.

Watch How it All Works

Watch How it All Works

In the first video below, we’ll go over some basic functionality and explain some of the data you’ll see in the reports.

Starting with TeE-Times will get you a new and improved environment. Techs clock in on the tablet and all they need to do for proper reporting is

- Open the vehicle (Repair Order) on the tablet when they start working on it

- Set the job line as done when they are done

- Close the vehicle (Repair Order) when they switch to other vehicles

As long as Service Advisors move the vehicle through the workflow and have the vehicle in “Pick-Up” on payday, you will be impressed with how easy it is.

Tech Efficiency at Pick-Up vs. RO Closed Out

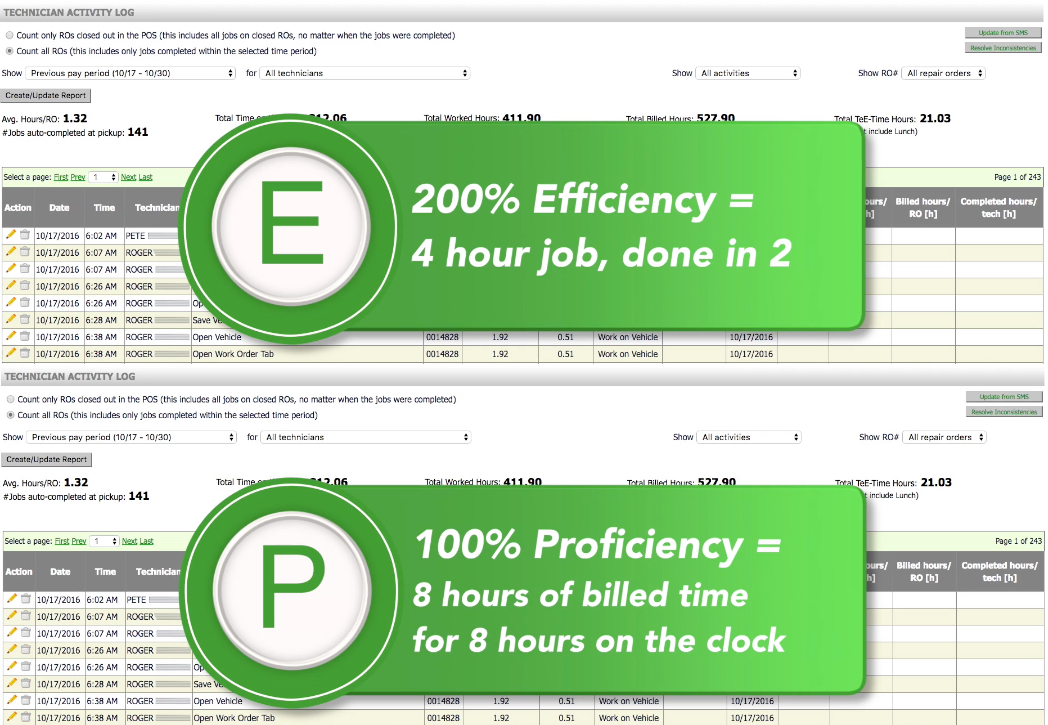

Technician Efficiency (the time billed to the customer divided by the time worked on the vehicle/repair order) is an incredibly valuable KPI for shop owners and managers to determine how fast technicians are able to finish the work and/or how good the estimate process is.

Excellent technicians perform work at efficiency rates of 90% to 140%

The TeE-Times concept allows for calculating the technician’s efficiency accurately. Traditionally, technician efficiency cannot be calculated accurately since Point of Sale (PoS) systems only allow the calculations for repair orders closed out in the PoS. If the technician has finished the work and payday has come, but the RO is not closed out yet, the billed time is not available in the report, but the work has been done. This leads to inaccurate tech efficiency values. Many shop owners then average the Tech efficiency over many months to eliminate the error, but that makes monitoring difficult.

Traditionally, technician efficiency cannot be calculated accurately since Point of Sale (PoS) systems only allow the calculations for repair orders closed out in the PoS. If the technician has finished the work, and payday has come, but the RO is not closed out yet, the billed time is not available in the report, but the work has been done. Worse, billed hours from ROs closed out in this time period, but the work done in the pay period before gets added to this pay period. This leads to inaccurate tech efficiency values.

Many shop owners then average the tech efficiency over many months to eliminate the error, but that method makes monitoring on a weekly or even monthly basis to give feedback to the techs and instill positive change impossible.

The TeE-Times system allows calculating the technician efficiency accurately since it uses the pickup workflow step as the trigger to calculate the worked hours and billed hours. Moreover, it allows for calculating the tech efficiency for both methods and comparing both values. In the image below, the setting for creating any TeE-Time report can be set for either.

- Only use ROs closed out already, or

- Use all ROs, which are closed out or in Pick-Up

What Techs Need to Do

Technicians follow a simple set of rules:

- Open the repair order on the tablet by tapping the vehicle image when they start working on it

- Set the job line as done when they are done

- Close the repair order when they switch to other vehicles or submit the vehicle when all work is done.

What SAs Need To Do

Service Advisors follow an even simpler set of rules:

- Move the vehicle from workflow step to step as the repair order travels through the workflow

- Make sure the vehicle is in pick-up when the work is done by technicians, and the customer can be called for pick-up

Technician Productivity

Technician Productivity is the number of hours the technician spent working on vehicles divided by the time the technicians are clocked in for the day. In other words, only the time truly used to work on vehicles is measured against the hours the tech is available at the shop to work on vehicles. It represents the ability of the Service Advisors to keep the Technicians busy (or lack of available vehicles in the shop to work on).

Technician Productivity is used to measure the degree of technician utilization. Values of 80-90% show the ability of the service advisor to keep technicians ‘busy’.

Sometimes shop managers see incredibly high values of technician efficiency, but extremely low tech productivity values at the same time. That indicates that technicians don’t leave the repair order open on the tablet while working on the vehicle at hand. Instead, they just open the repair order to see what needs to be done and then close it again.

Train your techs to leave the repair order while working on it and have the tablet with them at all times.

Technician Proficiency

Technician Proficiency is the number of hours billed divided by the amount of time a technician is available at work.

In other words, it combines Technician Efficiency and Productivity into one KPI. Best practices in The Digital Shop® enable shops to score between 80% and 110% Technician Proficiency.

If your numbers are below 70% and the technician efficiency is less than 70% as well, most likely the technicians are not efficient enough to finish the work assigned, waiting for parts for too long w/o having work at hand, or the billed hours charged to customers are too low.

Capture Unbillable Hours

With TeE-Times, technicians can mark on the tablet the kind of (unbillable) work they are busy with at the moment. Generating the TeE-Times report will allow you to find out where the lion’s share of unbillable time goes and adjust the behavior.

See below for typical TeE-Time codes. They are completely customizable for your needs.

Before TeE-Times

In the paper-based process, when job timers are used the following activities are required from the technician. Each is error-prone and requires one to leave the work on the vehicle and thus waste precious time:

- Punch in when coming to work or going for lunch or another break,

- Punch out when returning from lunch or a break, and when leaving the shop

- Start job timers on a computer away from the vehicle

- Stop job timers

In addition, technicians have to maintain a flag sheet manually to see their own progress and go over the payroll report with the owner at the end of the pay period to make sure it matches their own tracking.

TeE-Times allows the technician to see their finished hours and predicted work finished at the end of the pay period, both updated in real-time.

Best Practice

In order to take advantage of TeE-Times fully, the Digital Standard Operating Procedure is the best guidance to organize the workflow in the shop. Please see here for more details.

Quantified Benefits

TeE-Times will enable

- More consistency in

- Technician behavior and reduce fluctuations in Technician Efficiency by 30-40%

- Calculating the payroll values, reducing the error rate by at least 80%

- Higher confidence by Service Advisors and Technicians

- Resulting in higher morale

- Especially in seeing how more efficient work pays off in higher pay

DST & Training

During the one-day Digital Supervisor Training, you will experience hands-on how to create TeE-Time reports for your PoS and how to use the reports for Payroll and running your shop.

Check out the location in your area, where you can sign up for the Digital Supervisor Training here